CNC Machining Spare Die Casting Parts For Furniture

1.We can in accordance with the requirements of you to help you make the molds

2.The newest Yizhimi, Toshiba and Lijin die-casting machines can control the aluminum alloy die-casting parts without sand holes and pits

3.2 days sample preparation, 20 days fast delivery, efficient supply capacity of 300 tons of materials per month.

4.20 engineers and own tooling house,strong at OEM.

5.Tonnage of die-casting machine :160T to 800T

6.Respond quickly to every customer question

Details

Brief Introduction To Aluminum Die Casting Products

Aluminum die casting is a kind of die casting parts. Aluminum die castings are aluminum parts or aluminum alloy parts with the shape and size limited by the mold, which are cast by the die-casting machine using the die-casting machine that has installed the casting mold to pour the aluminum or aluminum alloy heated to liquid into the feeding port of the die-casting machine. Such parts are usually called aluminum die castings

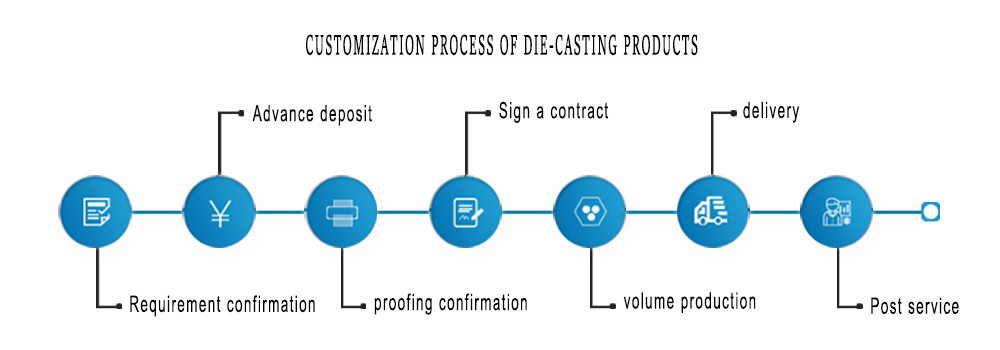

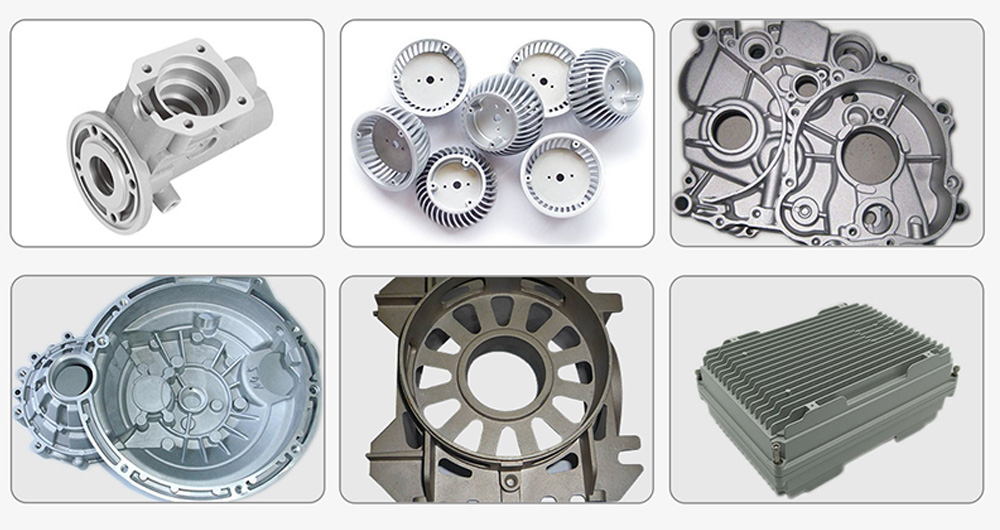

We are specialized in die-casting auto parts, furniture accessories, household appliances accessories, mechanical parts, communication accessories, etc。We provide one-stop service including die casting mold design and manufacturing, aluminum alloy die casting, zinc alloy die casting, processing customization, surface treatment.Welcome to customize with drawings and samples

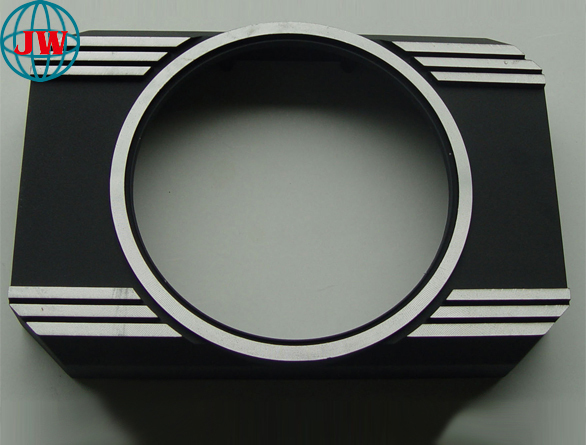

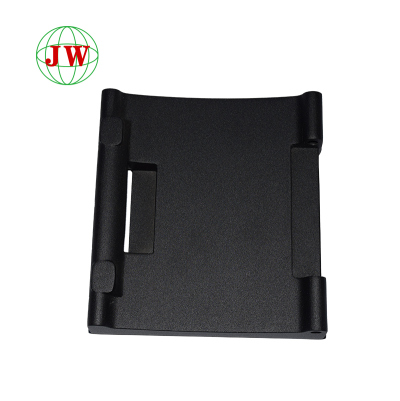

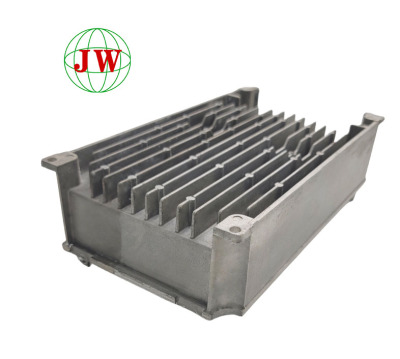

Sample Case:

Product Material: environment-friendly aluminum alloy ADC12, ADC1, A380, A360, Alsi9cu3, Alsi12Cu1Fe, LM25, etc.,We can customize the materials specified by customers

Surface Treatment: ultrasonic cleaning, vibration, grinding, polishing, sand blasting, painting, powder spraying, electroplating, oxidation, etc.

Workshop Display:

| ||

| Die Casting Workshop | ||

|  |  |

| CNC Finishing Workshop | Testing Center | Mold Workshop |

Surface Treatment

|  |  |

| TM Wave | Grind | Polishing |

|  |  |

| Ultrasonic Cleaning | Sandblasting | Painting and powder spraying |

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)