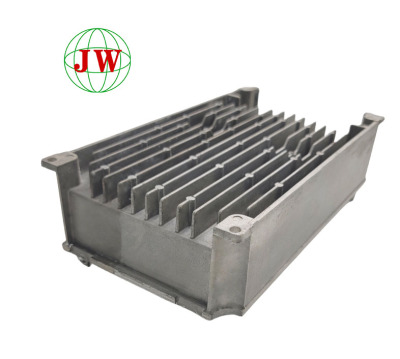

Aluminum Alloy Lock Housing Gravity Die Casting Parts

1. 30-year experience in aluminum tooling‘s factory with 2000+ tooling designs

2.20 engineers and own tooling house,strong at OEM.

3.2 days sample preparation, 20 days fast delivery, efficient supply capacity of 300 tons of materials per month.

4.The newest Yizhimi, Toshiba and Lijin die-casting machines can control the aluminum alloy die-casting parts without sand holes and pits

5.The density of die casting finished products is uniform, the products are not easy to break, deform, and stable in quality

Details

Jiawei die-casting factory was established in 1992, mainly engaged in aluminum alloy die-casting production and post-process supporting processing services. The factory is equipped with advanced technology and strong mold design and manufacturing center, and the quality of products and delivery time are the most fundamental guarantee. Die casting products are widely used in automobile, electronic communication equipment, motor, furniture, lighting and other fields. 60% of the products are directly or indirectly exported to Europe and the United States and other countries.

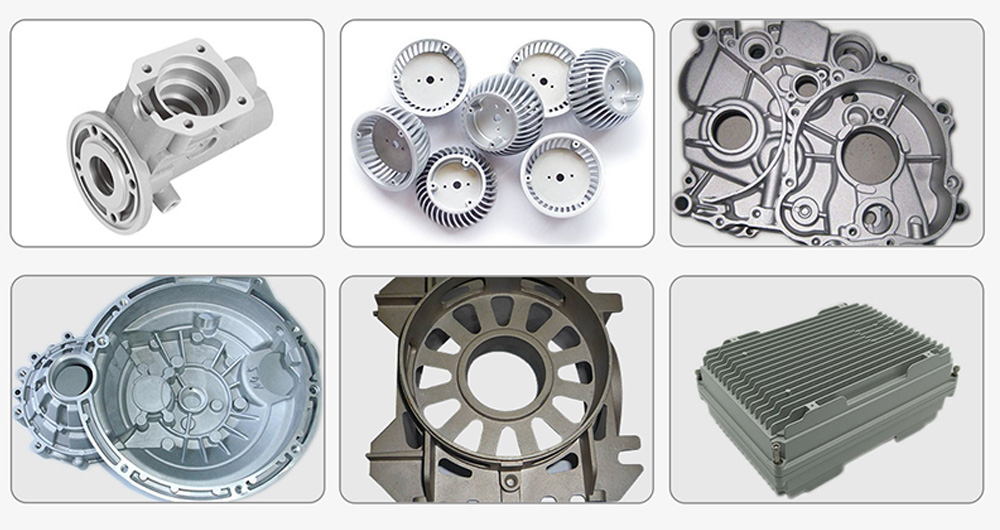

Sample Case:

Product Material: environment-friendly aluminum alloy ADC12, ADC1, A380, A360, Alsi9cu3, Alsi12Cu1Fe, LM25, etc.,We can customize the materials specified by customers

Surface Treatment: ultrasonic cleaning, vibration, grinding, polishing, sand blasting, painting, powder spraying, electroplating, oxidation, etc.

Workshop Display:

| ||

| Die Casting Workshop | ||

|  |  |

| CNC Finishing Workshop | Testing Center | Mold Workshop |

Surface Treatment

|  |  |

| TM Wave | Grind | Polishing |

|  |  |

| Ultrasonic Cleaning | Sandblasting | Painting and powder spraying |

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)