In today's rapidly evolving technological landscape, communication componentsplay a crucial role in ensuring seamless connectivity and efficient transmission of signals. As the demand for high-performance communication devices continues to grow, the quality and precision of communication component manufacturing become paramount. This is where die-casting solutions come into play, offering a reliable and efficient method for producing complex communication components.

Die casting is a manufacturing process that involves forcing molten metal under high pressure into a mold cavity. This process allows for the production of intricate shapes with high dimensional accuracy and excellent surface finish. When it comes to communication components, die casting offers several advantages over other manufacturing methods.

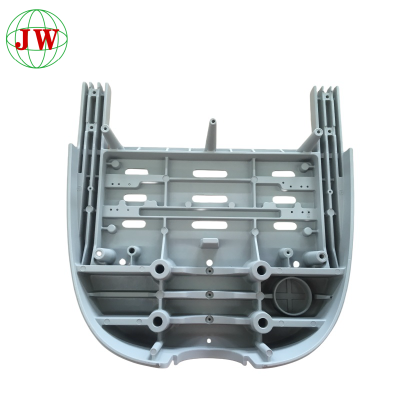

One of the key advantages of die casting for communication components is its ability to produce complex geometries. Communication devices often require components with intricate shapes and features to fit into tight spaces and perform specific functions. Die casting can easily handle these complex designs, ensuring that the components meet the exact specifications required for optimal performance.

Another benefit of die casting is its high production efficiency. The process can produce large quantities of components in a relatively short amount of time, making it ideal for meeting the high-volume demands of the communication industry. Additionally, die casting can be automated, further increasing production speed and reducing labor costs.

In addition to die casting, casting tooling also plays a crucial role in the production of communication components. Casting tooling refers to the molds and dies used in the die casting process. High-quality casting tooling is essential for ensuring consistent part quality and dimensional accuracy.

Our communication component die-casting solution combines state-of-the-art die casting technology with precision casting tooling to meet the most stringent technical requirements. Our team of experienced engineers and technicians work closely with customers to understand their specific needs and develop customized solutions that meet their unique requirements.

We start by carefully analyzing the technical specifications of the communication component to be produced. This includes factors such as size, shape, material requirements, and performance specifications. Based on this analysis, we design and manufacture casting tooling that is optimized for the specific component.

Our casting tooling is made from high-quality materials and is precision-machined to ensure accurate dimensions and smooth surface finishes. We use advanced CAD/CAM software and machining technologies to ensure that the tooling is designed and manufactured to the highest standards.

Once the casting tooling is ready, we begin the die casting process. Our die casting machines are equipped with the latest technology and are capable of producing components with high dimensional accuracy and excellent surface finish. We use a variety of alloys to meet the specific material requirements of different communication components.

During the die casting process, we closely monitor and control various parameters such as temperature, pressure, and injection speed to ensure consistent part quality. Our quality control team conducts rigorous inspections at every stage of the production process to ensure that the components meet the required technical specifications.

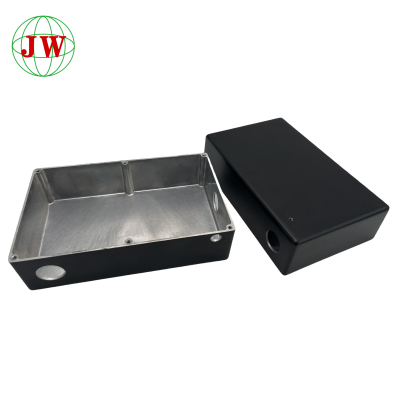

In addition to die casting and casting tooling, we also offer a range of value-added services to further enhance the quality and performance of communication components. These services include surface treatment, machining, assembly, and testing.

Surface treatment options such as plating, painting, and anodizing can be applied to improve the corrosion resistance and aesthetic appearance of the components. Machining operations such as drilling, milling, and tapping can be performed to add additional features and functionality to the components. Assembly services can be provided to combine multiple components into a complete subassembly or final product. And finally, testing services such as electrical testing, mechanical testing, and environmental testing can be conducted to ensure that the components meet the required performance standards.

So, does our communication component die-casting solution meet your technical requirements? The answer is yes. Our comprehensive die-casting solution, combined with our expertise in casting tooling and value-added services, offers a one-stop-shop for all your communication component manufacturing needs. Whether you need high-volume production of complex components or customized solutions for unique applications, we have the capabilities and experience to deliver results that exceed your expectations.

Contact us today to learn more about our communication component die-casting solution and how we can help you meet your technical requirements.