Why Choose Our Furniture Component Die-Casting Instead of Traditional Manufacturing Methods?

2024-08-23 16:45

Introduction: Welcome to our innovative furniture component die-castingservice. We understand that choosing the right manufacturing method for your furniture components can be a daunting task. That's why we are here to guide you through the benefits of our furniture component die-casting processand why it outperforms traditional manufacturing methods.

Body: Attention-grabbing introduction: Are you tired of dealing with subpar furniture componentsthat lack durability and precision? Look no further than our furniture component die-castingservice. We specialize in creating high-quality, long-lasting furniture components using advanced die-casting techniques.

The importance of quality furniture components: Furniture components play a crucial role in the overall functionality and aesthetic appeal of any piece of furniture. They need to be strong, reliable, and precise to ensure a seamless user experience. With our furniture component die-casting process, we guarantee superior quality components that meet these requirements and exceed your expectations.

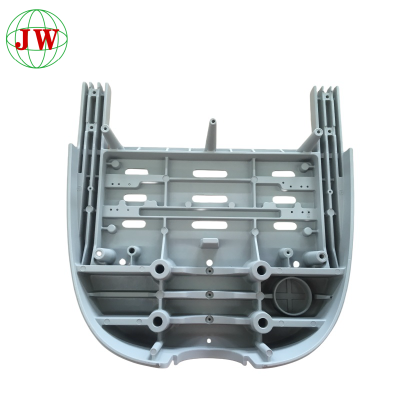

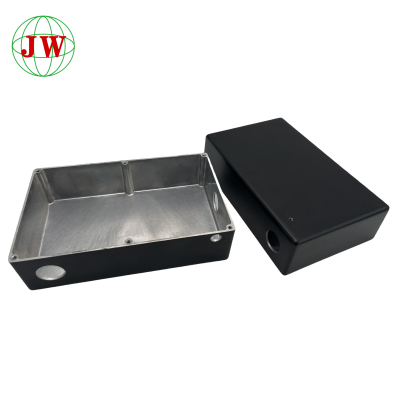

What is die casting? Die casting is a manufacturing process that involves injecting molten metal under high pressure into a mold cavity. This creates a precise, intricate shape that cools and solidifies to form the desired component. Die casting offers several advantages over traditional manufacturing methods, including improved accuracy, reduced waste, and increased productivity.

Benefits of our furniture component die-casting process:

1.Superior Quality: Our die-casting process ensures consistent quality and precision in every component we produce. The resulting components are stronger, more durable, and have a smoother finish compared to those made using traditional manufacturing methods.

2.Cost-Effective: By reducing waste and increasing productivity, our die-casting process allows us to offer competitive pricing without sacrificing quality. You get high-quality components at a fraction of the cost of traditional manufacturing methods.

3.Time-Efficient: Our die-casting process significantly reduces production time, allowing us to deliver your furniture components faster than traditional manufacturing methods. This means you can get your products to market sooner and stay ahead of the competition.

4.Customization: With our die-casting process, we can easily customize your furniture components to meet your specific needs. Whether you require unique shapes or specialized features, we can accommodate your requests and provide you with exactly what you need.

5.Environmentally Friendly: Our die-casting process produces less waste compared to traditional manufacturing methods, making it an eco-friendly option for producing furniture components. By choosing our service, you contribute to reducing environmental pollution and promoting sustainability.

Conclusion: In conclusion, choosing our furniture component die-casting service over traditional manufacturing methods offers numerous benefits, including superior quality, cost-effectiveness, time efficiency, customization options, and environmental friendliness. Don't settle for subpar furniture components when you can have the best with our die-casting process. Contact us today to learn more about how we can help you achieve your furniture component goals.

Get the latest price? We'll respond as soon as possible(within 12 hours)