Do you want to understand the production process of communication component die-casting?

2024-11-28 15:00

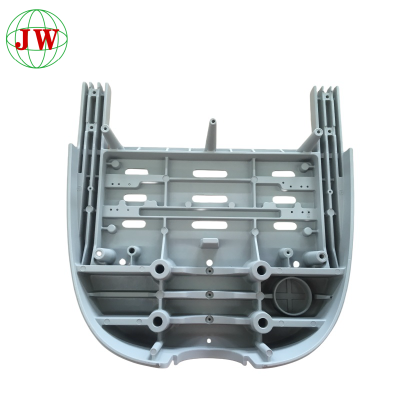

The production process of communication component die - casting is a sophisticated and highly technical sequence of operations. It begins with the design and engineering phase. Engineers meticulously design the communication component, taking into account its specific functions, dimensions, and performance requirements. This involves using advanced computer - aided design (CAD) software to create a detailed 3D model of the component. The design must consider factors such as signal transmission paths, heat dissipation, and the ability to integrate with other parts of the communication device.

Once the design is finalized, the next crucial step is the mold making process. High - quality molds are essential for die - casting. The molds are typically made from hardened steel or other durable materials. Skilled toolmakers use precision machining techniques to create the cavities and cores of the mold, ensuring that they match the exact specifications of the component design. The surface finish of the mold is also of great importance as it directly affects the surface quality of the final cast component. For example, a smooth mold surface will result in a smoother surface on the communication component, which is beneficial for minimizing signal interference.

After the mold is ready, the die - casting operation commences. The most commonly used die - casting method for communication components is high - pressure die - casting. Molten metal, often aluminum or zinc alloys due to their good electrical and thermal conductivity properties, is heated to a specific temperature and then injected into the mold cavity under high pressure. The high pressure ensures that the molten metal fills every intricate detail of the mold, producing a component with precise dimensions and complex geometries. For instance, small connectors or housings for communication devices with fine internal structures and external features can be accurately manufactured through this process.

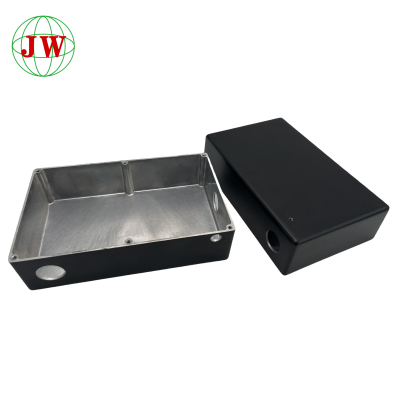

Following the die - casting, the components go through a finishing and quality control stage. This includes processes such as trimming the excess material, known as flash, from the cast parts. The surface of the components may also undergo treatments like polishing, plating, or painting to enhance their appearance and protect them from corrosion. Quality control is a strict and essential part of the process. Advanced inspection techniques, such as using coordinate measuring machines (CMMs) and optical inspection systems, are employed to check the dimensions, surface quality, and internal integrity of the components. Any defective parts are identified and removed to ensure that only high - quality communication components reach the market.

In conclusion, the production process of communication component die - casting is a comprehensive and precise operation that requires a combination of advanced design, skilled mold making, efficient die - casting, and meticulous finishing and quality control. Each step is crucial in ensuring that the final communication components meet the high standards of the communication industry, enabling reliable signal transmission and efficient device operation

Get the latest price? We'll respond as soon as possible(within 12 hours)