Do you want to know the impact of furniture component die-casting on environmental protection?

2024-11-12 15:38

In today's manufacturing landscape, the die - casting process for furniture components has become a significant area of focus, especially when considering its implications for environmental protection.

The Die - Casting Process in Brief

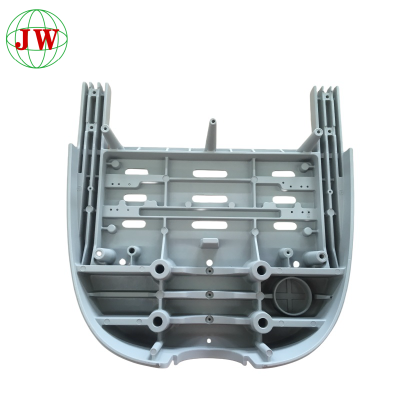

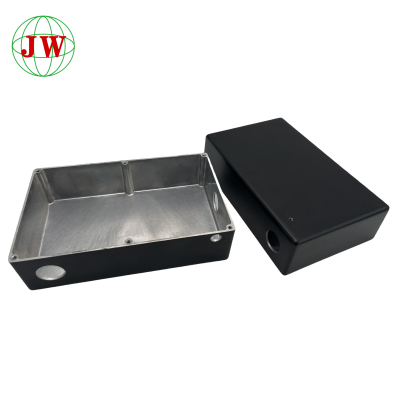

Die - casting is a manufacturing method that involves forcing molten metal under high pressure into a mold cavity. For furniture components, this process is often used to create parts with high precision and complex geometries. Commonly used metals in furniture die - casting include aluminum, zinc, and magnesium alloys. Aluminum, for instance, is popular due to its lightweight, durability, and recyclability.

Positive Environmental Impacts

Material Efficiency

One of the key advantages of die - casting in terms of environmental protection is material efficiency. The high - pressure injection process allows for the creation of complex shapes with minimal material waste. Compared to traditional manufacturing methods like forging or machining, die - casting can reduce the amount of raw material required. This not only conserves natural resources but also reduces the energy associated with extracting and processing additional materials. For example, in the production of aluminum furniture components, the precise nature of die - casting ensures that the aluminum is used optimally, minimizing scrap.

Recyclability

Most metals used in furniture die - casting, such as aluminum and zinc, are highly recyclable. At the end of a furniture's life cycle, these components can be collected, melted down, and reused in the die - casting process. This closed - loop recycling system significantly reduces the environmental impact. Recycled aluminum, for example, requires only a fraction of the energy needed to produce new aluminum from bauxite ore. This makes die - casting an environmentally friendly option from a long - term perspective, as it promotes the circular economy within the furniture manufacturing industry.

Challenges and Mitigation in Environmental Protection

Energy Consumption

However, the die - casting process is not without its environmental challenges. One of the main concerns is energy consumption. The high - pressure injection and melting of metals require significant amounts of energy. To address this, many die - casting facilities are now adopting energy - efficient technologies. For example, advanced melting furnaces with better insulation and heat recovery systems can reduce the energy needed to melt the metal. Additionally, optimizing the die - casting cycle time can also decrease overall energy consumption per part produced.

Emissions

Another issue is emissions during the die - casting process. When melting certain metals, there can be emissions of greenhouse gases and other pollutants. To mitigate this, proper ventilation and air - purification systems are essential. Some companies are also exploring alternative melting techniques that produce fewer emissions. For instance, using induction melting for certain alloys can reduce the emissions associated with traditional fuel - based melting methods.

In conclusion, the impact of furniture component die - casting on environmental protection is a complex issue with both positive and negative aspects. By focusing on material efficiency, recyclability, and implementing measures to reduce energy consumption and emissions, the die - casting process can be made more environmentally friendly. This will not only benefit the environment but also contribute to the sustainability of the furniture manufacturing industry as a whole

Get the latest price? We'll respond as soon as possible(within 12 hours)