A new method for deburring aluminum alloy die-casting parts, worth collecting!

2023-05-18 15:30

In response to the problem of burrs in die-casting parts of optoelectronic product bases, the reasons for their occurrence and removal methods were analyzed, and preventive measures and new removal technologies were proposed, that is, by controlling the die-casting process parameters and adjusting the mold structure to avoid the generation of burrs, a new thermal energy deburring technology was used to remove burrs. These two methods have the characteristics of wide applicability, simple fixtures, low cost, fast processing capacity, and short cycle time.

In die-casting production, metal flakes appear on the parting surface and core matching edge of die-casting parts, which we call burrs. The existence of burrs is the most common problem in die castings, which not only affects the size and assembly accuracy of the product, but also seriously affects the appearance of the product. The amount of burrs is one of the important indicators to measure the quality of die castings. The more burrs there are, the lower the quality standard.

In actual industrial production, there is no fundamental solution for various enterprises to completely solve the problem of deburring die castings. In a sense, the emergence of burrs still carries the objective existence and inevitability of the industry. The main reasons for its occurrence are that the dynamic and fixed molds of the mold are not properly matched, the various injection conditions of the die-casting machine are not adjusted to the optimal state, and the mold structure, such as runner and exhaust design, is unreasonable. Moreover, even if there are no issues with the aforementioned factors, the initially produced products do not have burrs. However, over time, dirt, wear, and other reasons inside the mold can also cause burrs in the products produced by the mold. The resulting repeated mold washing and repair can also affect production efficiency and the lifespan of the mold. From this, it can be seen that the analysis of burrs in die castings and the study of burr removal methods have important practical value. This article analyzes the causes of burrs in the die-casting parts of a certain optoelectronic product base, and proposes targeted, reasonable and effective prevention and removal plans for burrs.

1. Formation and Cause Analysis of Burrs in Die Castings

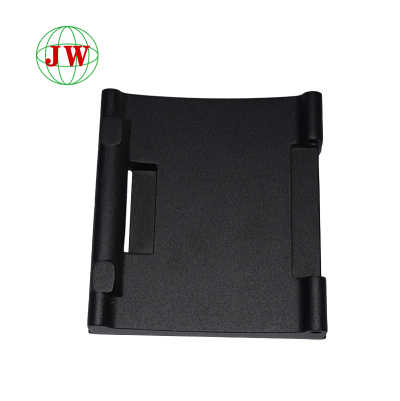

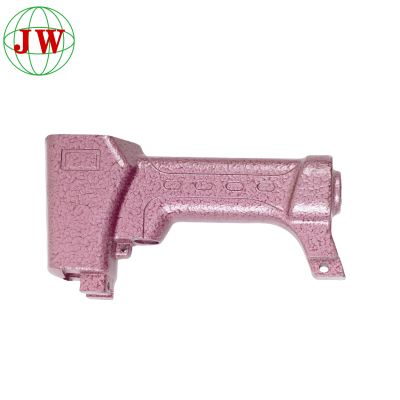

The three-dimensional solid of the analyzed aluminum die casting is shown in Figure 1. It needs to be equipped with nearly 50 precision lenses, bearings, coils, etc

The minimum positional tolerance of the main, secondary, and holes in the X, Y, and Z axes of the parts is 0.005 mm, and the installation angle deviation of each lens is below 0.5 °. It belongs to precision die castings, and the control of burrs is also very strict. We found through statistical analysis of engineering adverse information of this product in recent years that burrs are one of the main factors affecting its quality.

Below, we will conduct a specific analysis of the burrs and their causes in the above areas.

2. Measures for removing burrs

2.1 Avoiding Burrs

In the production process, the factors that cause burrs are multifaceted, mainly including the stability of die casting machine performance, selection of die casting process parameters, alloy composition and melting process, use of release agents, reasonable mold structure, and manufacturing quality. From Engineering

A new method for deburring aluminum alloy die-casting parts, worth collecting!

In fact, the performance and mold structure of die-casting machines are rarely changed. Therefore, it is particularly important to adjust the die-casting process parameters and make simple repairs to the mold to improve product quality. This article combines practical experience to summarize the reasons and preventive measures for possible burrs in die-casting molds and process parameters, as shown in Tables 2 and 3.

Therefore, based on the above analysis, it is believed that the actual operation can start by adjusting the die casting process parameters, which can avoid the generation of burrs during the forming stage and save the subsequent deburring process. For example, the peripheral burrs of the die castings in this article have a low defect rate and some instability. Upon checking the injection speed at that time, it was also higher than the standard setting value. The injection speed was adjusted back from 0.9 to 0.8, and the mold temperature was maintained at 90-95 ℃. The burrs disappeared.

For example, 6 burrs (secondary shaft side burrs): there are line burrs on the end surface of the quasi 12 hole, with a thickness of 0.02 mm, which is difficult to remove in subsequent processes. Check the condition of the mold because Φ There is mutual movement between the 12 mm hole core pulling slider and the cavity insert, resulting in wear and gaps over time. During die casting, aluminum liquid is infiltrated and line burrs are generated. A 0.02 mm gasket is welded to the worn part of the slider, and the burrs disappear.

2.2 Traditional deburring methods

The traditional deburring method for die castings is to manually remove the burrs one by one by using hand tool such as files and cutters. This method consumes a long time, has low production efficiency, and, like the precision die castings in this article, has high precision requirements, so manual deburring cannot meet the use requirements. In addition, when using a stamping die to remove the riser, the burrs on the outer circumference of the casting can also be removed, but this method cannot remove the burrs on the internal structure and details.

2.3 New methods for deburring

A new technology for deburring is thermal deburring. The working principle of thermal deburring is to place the parts that need to be deburred in a closed container, and then fill them with a certain amount of hydrogen (or methane) and oxygen. After being ignited by a spark plug, the mixed gas reacts in an instant, releasing a large amount of heat, causing the burrs (burrs) to self ignite under high temperature (about 3000 ℃), high pressure (20 times the inflation pressure), and high speed (8 times the speed of sound), in order to achieve the purpose of deburring (flash) removal.

Compared to the substrate of a part, burrs have a large surface area and a relatively small volume, which can absorb more heat. Additionally, due to the excellent penetration of gas and the absence of pores, they have a good removal effect on burrs in parts that are difficult to remove by hand. The root of the burr is usually relatively thin and thin, which can effectively suppress the transfer of heat to the interior of the part. Moreover, the reaction time is very short, so only small burrs can be burned and removed. Due to the fact that the generated heat does not have any impact on the main body of the part, it generally does not cause any changes in the basic performance of the part, and the efficiency of deburring is very high, with stable process performance.

A new method for deburring aluminum alloy die-casting parts, worth collecting!

Using previous methods, it was difficult to ensure the quality of deburring and the effect was unstable. After assembly, residual burrs peeled off due to fluid action, which may affect the performance of the product. However, thermal deburring method has a good effect on such products. After removing the burrs on the casting using a thermal burr machine, it can be seen that the burrs on the casting have been basically removed without any residue, and there has been no secondary damage to the product, especially in small parts with complex shapes.

3. Conclusion

By analyzing the causes and removal methods of burrs in the die-casting parts of optoelectronic product bases, two feasible solutions are proposed: firstly, by controlling the die-casting process parameters and adjusting the mold structure to avoid burrs; The second is to use a new technology - thermal deburring method to remove burrs, which has the characteristics of wide applicability, simple fixture, low cost, fast processing capacity, and short cycle time.

Get the latest price? We'll respond as soon as possible(within 12 hours)