What are the differences between die-casting aluminum and aluminum alloys?

2023-05-17 15:30

What are the differences between die-casting aluminum and aluminum alloys?

Die cast aluminum and aluminum alloy are two common industrial materials, which have significant differences in performance, manufacturing process, application scenarios, and other aspects. The following will elaborate on material composition, manufacturing process, performance comparison, and other aspects one by one.

1、 Material composition

Die cast aluminum is a high-strength and high toughness aluminum alloy, typically composed of over 80% aluminum, over 20% silicon, over 1% iron, and other trace elements. Aluminum alloy is an alloy composed of various metal elements such as aluminum, magnesium, copper, zinc, etc., which has higher strength and hardness.

2、 Manufacturing process

The manufacturing process of die-casting aluminum involves injecting molten aluminum alloy into a mold, cooling it, and forming a casting. The manufacturing process of aluminum alloy involves pouring molten metal into a mold and cooling it to form a casting. The difference between the two processes is that the manufacturing process of die-casting aluminum requires pressure processing of the aluminum alloy to obtain the required shape and

3、 Performance Comparison

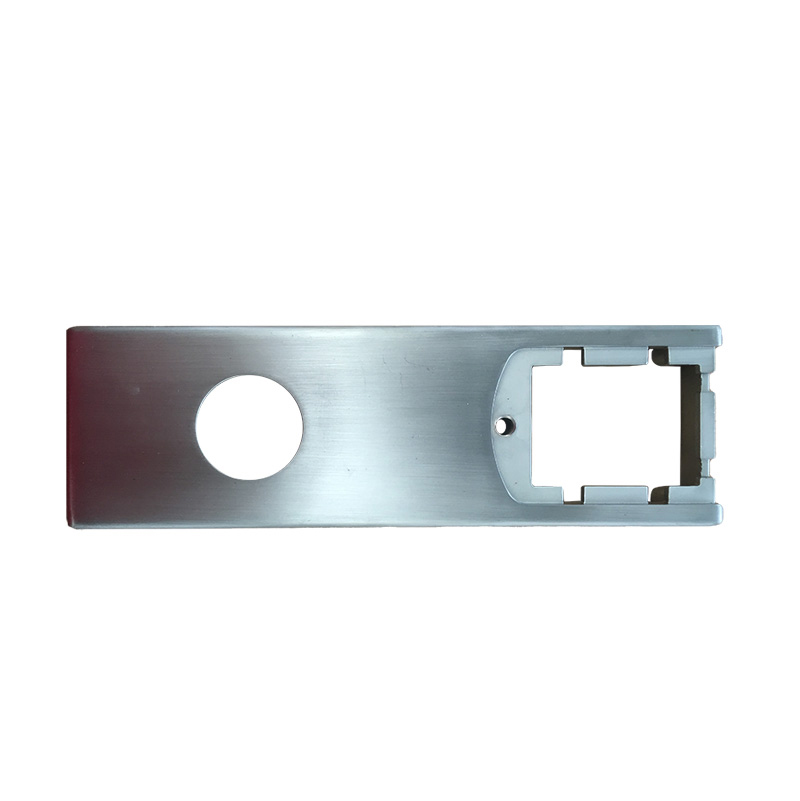

Die cast aluminum has higher strength and hardness, but lower density, resulting in a lighter weight. Aluminum alloys have higher density and strength, but relatively lower strength and hardness. Therefore, die-casting aluminum is suitable for manufacturing products with high strength and lightweight, such as mobile phones, tablets, etc; Aluminum alloys are suitable for manufacturing products that require high strength and corrosion resistance, such as automobiles, aerospace, etc.

What are the differences between die-casting aluminum and aluminum alloys?

4、 Application Scenario

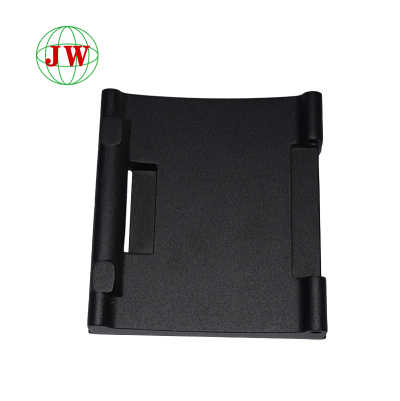

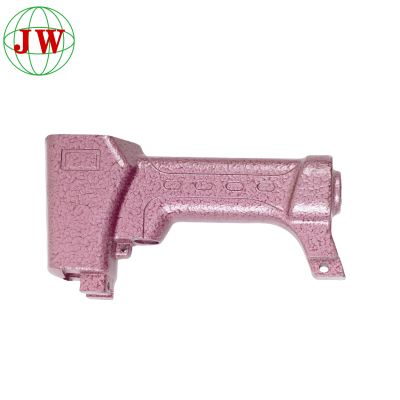

Die cast aluminum is suitable for manufacturing products with complex, fine, and large shapes, such as automotive engine shells, mechanical parts, etc; Aluminum alloy is suitable for manufacturing products with simple, large, and lightweight shapes, such as building exterior panels and electrical shells. In addition, die-casting aluminum can also improve its corrosion resistance and surface quality through surface treatment and other methods, making it suitable for manufacturing high-end products.

In short, die-casting aluminum and aluminum alloy are two different industrial materials, with significant differences in material composition, manufacturing process, performance comparison, and other aspects. Die cast aluminum is suitable for manufacturing products with complex, fine, and large shapes, while aluminum alloy is suitable for manufacturing products with simple, large, and lightweight shapes.

Get the latest price? We'll respond as soon as possible(within 12 hours)