Hot Products

About Us

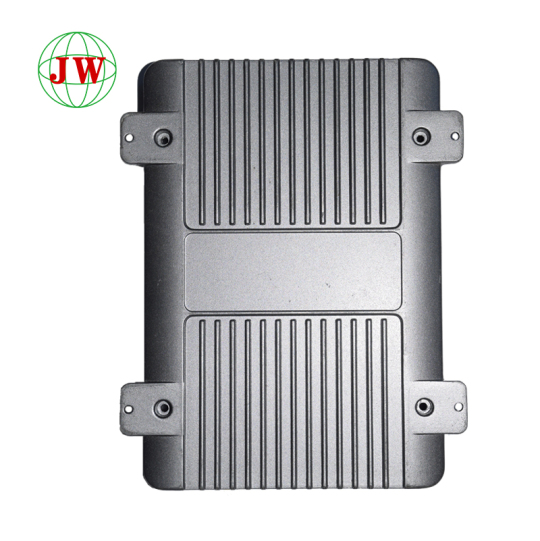

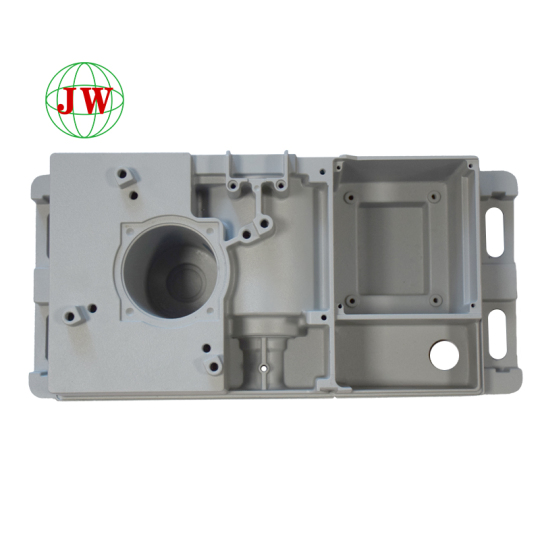

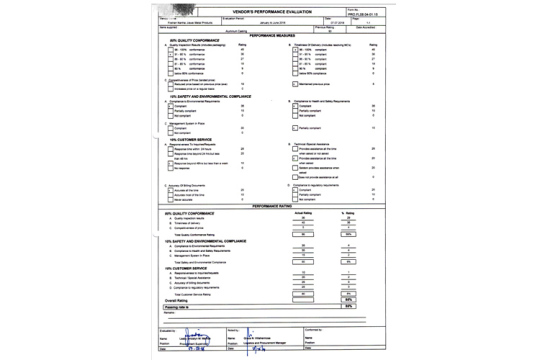

Foshan Nanhai Jiawei Metal Products Co., Ltd. has a history of more than 30 years since its establishment in 1992, with strong economic strength. With the rapid development of business, the production scale has also been expanding. In the second half of 2001, the new plant began to be built, and was completed and put into operation in 2003. Now the company covers an area of 21800 square meters, including 9500 square meters of factory buildings, 780 square meters of office buildings and 2780 square meters of dormitories. There are 165 employees, including 46 engineers and technicians.

More

News

-

05/05-2024

Innovative Non-Toxic Cookware Revolutionizes Culinary ExperienceIn the dynamic culinary industry, manufacturers are responding to the demand for safe and efficient cookware. Aluminum die-cast and non-stick cookware, alongside BBQ accessories and Teflon pans, are at the forefront. The quest for the best nontoxic nonstick pan has led to revolutionary advancements. Our company leads this charge with premium nontoxic nonstick cookware, boasting durability, safety, and performance. From aluminum die-cast durability to superior non-stick coatings, our products redefine culinary excellence.

-

02/03-2026

Aluminum Alloy Die-Casting Furniture Connectors & Molds: Innovations Shaping Modern Furniture ManufacturingDriven by precision and sustainability, aluminum alloy die-casting furniture connectors anddie-casting molds are reshaping modern furniture manufacturing. High-precision die-casting molds ensure die-cast connectors’ seamless assembly and durability, outperforming traditional hardware with one-piece structures. Trends focus on recycled aluminum for die-cast parts and smart integration. Asia-Pacific leads global production, with automation boosting efficiency. Die-casting technology will keep advancing in precision and eco-friendliness, empowering competitive advantages for enterprises with core die-casting mold technologies.

-

01/30-2026

Aluminum Die-Cast Building Accessories: Innovation and Sustainability Reshape Construction SectorAluminum die-cast accessories drive the construction industry’s upgrade, with die-cast building accessories favored for light weight and durability. Advanced die-casting tech and recycled materials boost sustainability. Asia-Pacific leads the market, with smart buildings fueling demand for high-performance, multi-functional aluminum die-cast products.