Brass Hot Forging Parts Investment CNC Machining Die Casting

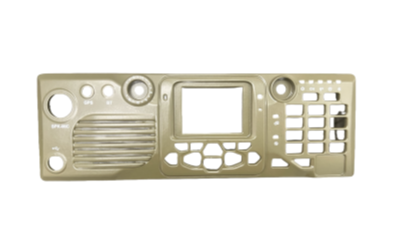

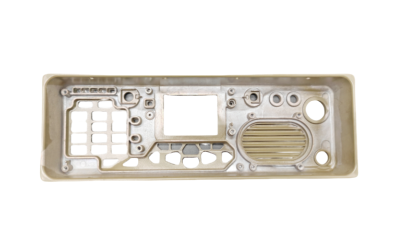

Powder Coating: Our communication box cover boasts a premium powder coating finish, ensuring long-lasting protection against corrosion and wear. The coating adds a sleek and professional appearance, enhancing the aesthetics of your equipment.

CNC Services: Leveraging cutting-edge CNC services, our cover is precisely machined to perfection. This technology allows for intricate detailing and customization, ensuring a precise fit and seamless integration with your communication box.

Die Cast Models: Incorporating die cast models into our cover design results in enhanced durability and structural integrity. The use of high-quality materials and advanced casting techniques ensures robustness and longevity, providing reliable protection for your communication equipment.

Die Casting Processing: Our cover undergoes meticulous die casting processing, resulting in a seamless and uniform construction. This manufacturing method allows for complex shapes and designs, optimizing functionality while maintaining a lightweight profile.

CNC Lathe: Utilizing CNC lathe technology, each aspect of our cover is meticulously crafted for precision and accuracy. This ensures that every detail, from the fitment to the finishing, meets the highest standards of quality and performance, guaranteeing a superior product for your communication needs.

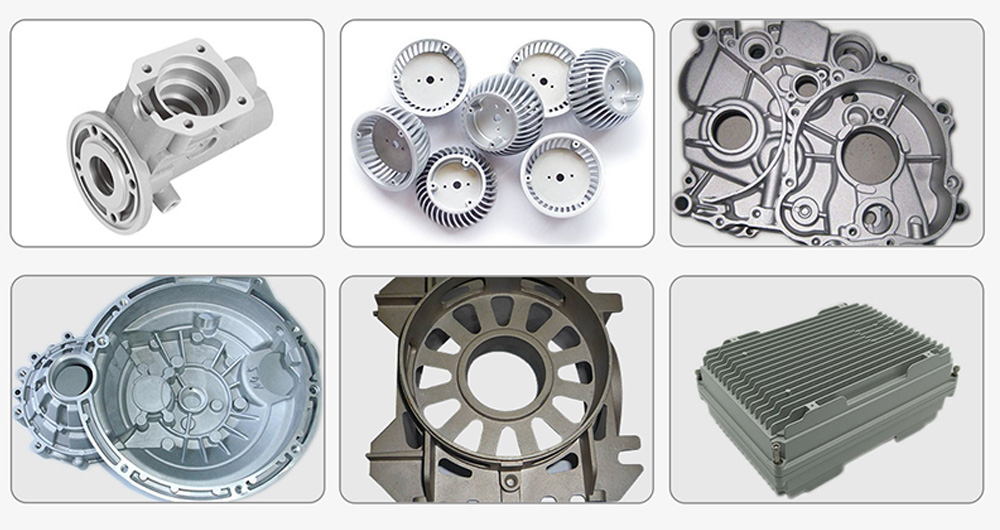

6.The density of die casting finished products is uniform, the products are not easy to break, deform, and stable in quality

7. More than 30 years of die casting experience

8.Advanced production corollary equipment

Details

About us

Introducing our innovative line of patented communication accessories for boxes, featuring powder coating, CNC services, and die-cast models.

Powder Coated Mounting Brackets: Securely attach your communication box with our powder-coated brackets, offering durability and corrosion resistance.

CNC Machined Antenna Holders: Ensure optimal signal reception with our CNC machined antenna holders, precisely crafted for stability and performance.

Die-Cast Model Locking Mechanisms: Safeguard your equipment with our die-cast model locking mechanisms, combining strength and precision for reliable security.

Powder Coated Cable Management Panels: Keep cables organized and protected with our powder-coated panels, designed for easy installation and maintenance.

CNC Machined Accessory Mounts: Customize your communication box with our CNC machined accessory mounts, offering versatility for additional components.

Die-Cast Model Hinges: Facilitate smooth opening and closing of your box with our die-cast model hinges, engineered for durability and longevity.

Powder Coated Ventilation Grilles: Maintain optimal airflow and temperature regulation with our powder-coated ventilation grilles, ensuring efficient cooling.

CNC Machined Nameplate Holders: Display identification labels with our CNC machined nameplate holders, providing a professional and durable solution.

Die-Cast Model Handles: Easily transport your box with our die-cast model handles, designed for ergonomic comfort and reliability.

Powder Coated Latches: Securely fasten your box with our powder-coated latches, offering strength and resistance to wear and tear.

From mounting brackets to latches, our range of communication accessories combines innovative design with premium materials for unmatched quality and performance.

Aluminium Die Casting Telecom Case Cover

Advantages of surface polishing on aluminum die castings: Enhanced aesthetics, improved corrosion resistance, and smoother texture for a refined finish.

Aluminium Die Casting Telecom Case Cover

Our company possesses die casting qualifications meeting military standards, ensuring reliability and performance for defense applications.

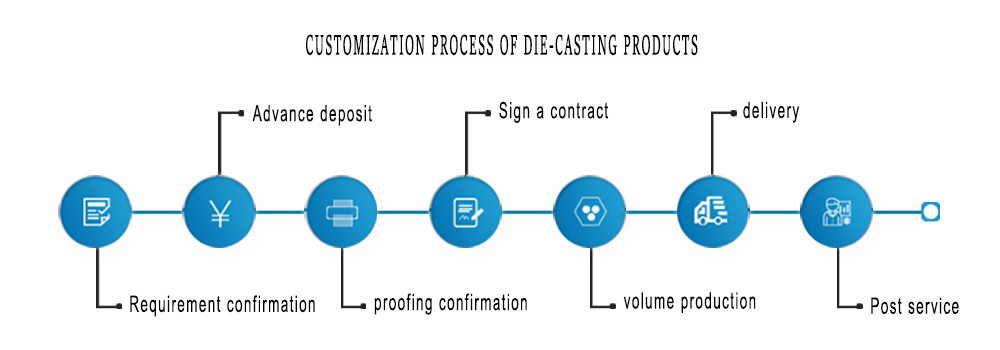

Sample Case:

Product Material: environment-friendly aluminum alloy ADC12, ADC1, A380, A360, Alsi9cu3, Alsi12Cu1Fe, LM25, etc.,We can customize the materials specified by customers

Surface Treatment: ultrasonic cleaning, vibration, grinding, polishing, sand blasting, painting, powder spraying, electroplating, oxidation, etc.

Workshop Display:

| ||

| Die Casting Workshop | ||

|  |  |

| CNC Finishing Workshop | Testing Center | Mold Workshop |

Surface Treatment

|  |  |

| TM Wave | Grind | Polishing |

|  |  |

| Ultrasonic Cleaning | Sandblasting | Painting and powder spraying |

Conclusion:

Thank you for joining us on this journey into the world of Custom CNC Machining Services company. At YuanZhong Precision, we take pride in our ability to deliver precision and personalization with every project we undertake. Whether you’re a seasoned industry player or a startup with a groundbreaking idea, we’re here to turn your vision into reality. Reach out to us today to explore the endless possibilities of custom CNC machining!

Cecilia

Vic

Luke

Sunny

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)