Which furniture parts are made by casting?

2024-07-30 15:00

Introduction: In the world of furniture manufacturing, casting is a crucial process that allows for the creation of intricate and durable parts. This article will explore which furniture parts are made by casting, focusing on the key terms of furniture parts, part casting, die casting mould, die casting parts, and furniture die casting.

Body: Furniture Parts: The term "furniture parts" refers to the various components that make up a piece of furniture, such as legs, frames, and connectors. These parts can be made from a variety of materials, including wood, metal, and plastic. In this context, we will focus on the metal parts that are created through casting processes.

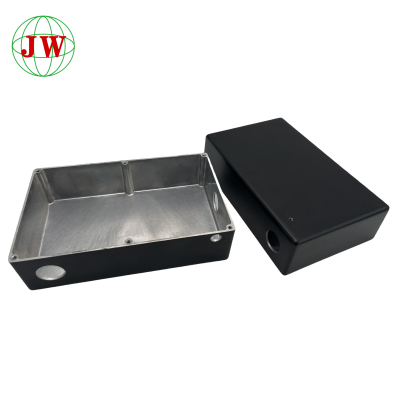

Part Casting: Part casting is a manufacturing technique that involves pouring molten metal into a mold cavity to create a desired shape. This process is used extensively in the production of furniture parts due to its ability to produce complex geometries and high-quality finishes. Some common types of part casting include sand casting, investment casting, and die casting.

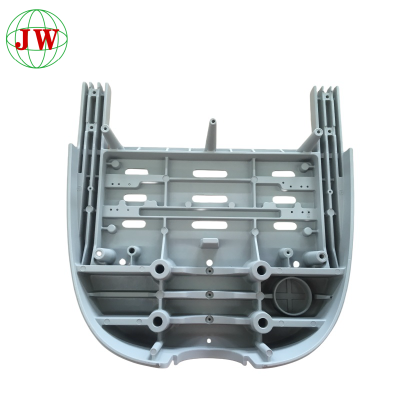

Die Casting Mould: A die casting mould is a specialized tool used in the die casting process to create precise and repeatable shapes. The mould is typically made from high-strength steel or other durable materials and consists of two halves that are separated after the casting process to reveal the finished part. Die casting moulds are essential for producing consistent and accurate furniture parts with minimal waste.

Die Casting Parts: Die casting parts are those created using the die casting process, which involves injecting molten metal under high pressure into a die casting mould. This method produces parts with smooth surfaces, tight tolerances, and excellent mechanical properties. Die casting is often used for furniture parts that require a high level of precision and strength, such as chair legs or table bases.

Furniture Die Casting: Furniture die casting refers specifically to the use of die casting techniques in the manufacture of furniture parts. This process allows for the creation of complex shapes and intricate designs that would be difficult or impossible to achieve through other manufacturing methods. By utilizing die casting, manufacturers can produce high-quality furniture parts with consistent dimensions and superior performance characteristics.

Conclusion: In conclusion, casting plays a vital role in the production of furniture parts, particularly when it comes to creating complex shapes and durable components. By understanding the key terms associated with part casting, die casting moulds, die casting parts, and furniture die casting, manufacturers can optimize their processes and produce exceptional furniture pieces that meet the demands of modern consumers. As technology continues to advance, it will be exciting to see how these techniques evolve and contribute to the future of furniture design and manufacturing.

Get the latest price? We'll respond as soon as possible(within 12 hours)