What must be paid attention to in zinc alloy die casting?

2023-02-01 11:41

What must be paid attention to in zinc alloy die casting?

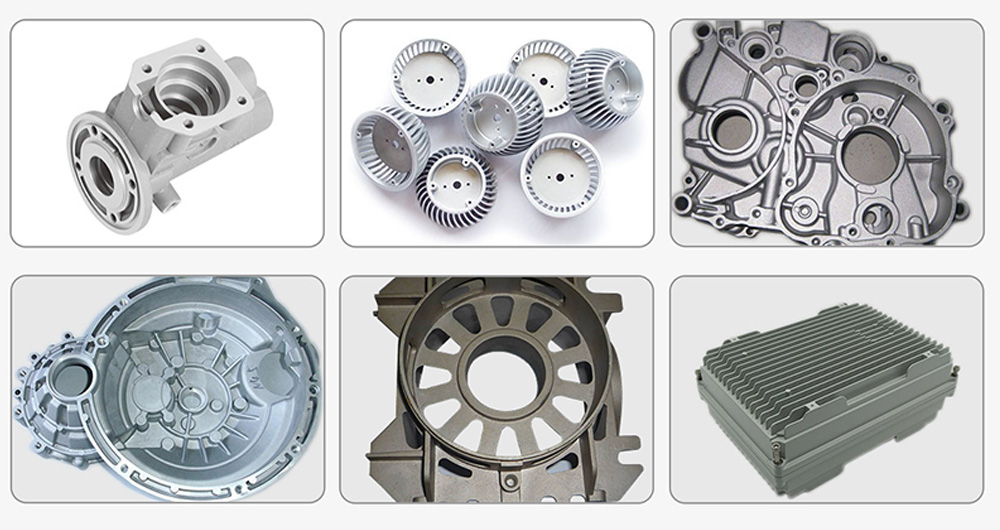

Zinc alloy die casting is a relatively common die casting, which is widely used in daily life. So what should be paid attention to when carrying out zinc alloy die casting? Let's take a look.

Zinc alloy die-casting is a kind of alloy die-casting. Therefore, when carrying out die-casting, attention should be paid to the use ratio between metals, adding a certain amount of magnesium, aluminum and copper for smelting. At the same time, in the production of zinc alloy die-casting, attention should be paid to the proportion of new and old raw materials. The ratio can be set as 7:3, which can reduce the loss of aluminum consumption of zinc alloy recasting.

Secondly, in the production of zinc alloy die-casting, after the production of raw materials, the temperature of melting nozzle material should be controlled to not exceed 430 ℃ to avoid metal loss due to high temperature.

Finally, zinc alloy die-casting should be produced in a centralized manner. Zinc alloy ingots should be produced in a smelting furnace under the same conditions, which can not only reduce the production cost of zinc alloy die-casting, but also ensure that the parameters of each process are accurate. Also pay attention to place the zinc alloy die-casting in a ventilated, clean and tidy place without moisture to prevent pollution

Get the latest price? We'll respond as soon as possible(within 12 hours)