What is the impact of communication component die-casting on product appearance?

2024-08-06 15:00

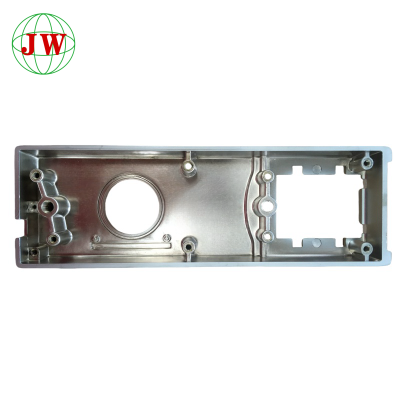

In the world of manufacturing, die-casting stands as a cornerstone for producing high-precision, complex metal components. When we delve into the domain of communication components, die-casting emerges not just as a fabrication technique but as an art form that significantly influences the final product's aesthetic appeal. This discourse aims to unravel the intricate relationship between communication component die-casting and its profound impact on product appearance.

Die-casting, with its ability to generate fine details and crisp edges, becomes paramount for communication components requiring precision and sophistication. The process involves injecting molten metal under high pressure into precisely engineered steel or alloy molds, known as die casting tooling. This method ensures consistent quality and dimensional accuracy, factors crucial for components that often serve as the face of technological devices, where even minor flaws can affect performance and perception.

The choice of material and the design of die casting tooling play decisive roles in determining the visual outcome. Quality tooling facilitates the seamless flow of metal, reducing defects such as misruns, cold shuts, and blisters, which could otherwise mar the surface of the cast component. Furthermore, the alloy composition and its fluidity during the casting process directly influence the finish, from the smoothness to the coloration and sheen of the metal.

Advanced die-casting techniques such as vacuum die-castingor low-pressure die-casting further refine the product's appearance by minimizing porosity and improving surface uniformity. These methods ensure that the finished communication component exhibits a polished look, free from the pitting and uneven textures associated with conventional die-casting processes.

Moreover, post-casting treatments like plating, anodizing, or painting can enhance the visual appeal of die-cast communication components. These processes not only provide a cosmetic upgrade but also offer protection against corrosion and wear, extending the lifespan and maintaining the attractiveness of the product over time.

In conclusion, the meticulous artistry involved in communication component die-casting significantly shapes the visual standards of the end product. From the initial design of die casting tooling to the selection of materials and casting techniques, every step is a critical decision that resonates in the finished item's aesthetic value. Embracing innovative die-casting technologies not only elevates product appearance but also mirrors the commitment to excellence in the fast-paced realm of communication technology.

This exploration underscores the vital synergy between die-casting craftsmanship and product aesthetics, highlighting how the former directly influences the latter in shaping user experiences and setting benchmarks for quality in the communication industry. As we forge ahead, understanding this impact becomes essential for those aiming to create products that stand out as much for their functionality as for their visual charm

Get the latest price? We'll respond as soon as possible(within 12 hours)