Latest Innovations and Investments in the Die Casting Industry

2024-05-21 11:22

Latest Developments in the Die Casting Industry: Expanding Horizons and Technological Advancements

May 21, 2024 - The die casting industry is witnessing significant advancements and expansions, marking a period of robust growth and innovation. Here are some of the latest updates shaping the future of die casting.

GF Casting Solutions to Establish New Plant in the U.S.

GF Casting Solutions has announced a major investment of $184 million to establish a new high-pressure die casting plant in Augusta, Georgia. Scheduled to commence production by 2027, this strategic move marks GF Casting Solutions' return to the U.S. market, aiming to cater to the growing demand for high-quality die cast components (Diecasting.org).

Ryobi's Major Investment in Mexico

Ryobi Die Casting is set to enhance its production capabilities with a $50 million investment in its aluminum die casting facility located in Irapauto, Mexico. This investment will bolster Ryobi’s capacity to meet the increasing demand for die-cast components across various industries (Diecasting.org).

General Motors Boosts Indiana Casting Plant

General Motors (GM) has announced a $45 million investment in its Bedford, Indiana casting plant. This funding will expand the production of drive unit castings, essential for GM's upcoming electric vehicles (EVs) such as the Chevy Silverado EV. This move underscores GM's commitment to advancing its EV lineup and supporting sustainable manufacturing practices (Diecasting.org).

YIZUMI Showcases Digitalized Die Casting Technology

At the 2024 Die Casting Congress in Ningbo, China, YIZUMI unveiled its latest digitalized die casting technology and LEAP ultra-large integrated die casting solutions. This technology is designed to enhance production efficiency and product performance, particularly in the new energy vehicle (NEV) sector. YIZUMI's advancements demonstrate significant strides in integrating digital solutions into traditional manufacturing processes, paving the way for future innovations (Yizumi).

Market Growth and Future Prospects

According to Grand View Research, the global aluminum die casting market is projected to grow at a compound annual growth rate (CAGR) of 5.4% from 2023 to 2030. This growth is driven by the increasing demand for lightweight materials in the automotive industry and the rising infrastructural developments in Asia. The market value is expected to reach $105.63 billion by 2030, reflecting the industry's expanding scope and potential (Grand View Research).

These developments highlight a dynamic phase for the die casting industry, characterized by significant investments, technological advancements, and a strong focus on sustainability and efficiency. As companies continue to innovate and expand, the industry is poised for sustained growth and transformative changes in the coming years.

For more information and detailed insights, visit our website:www.jiaweimetal.com

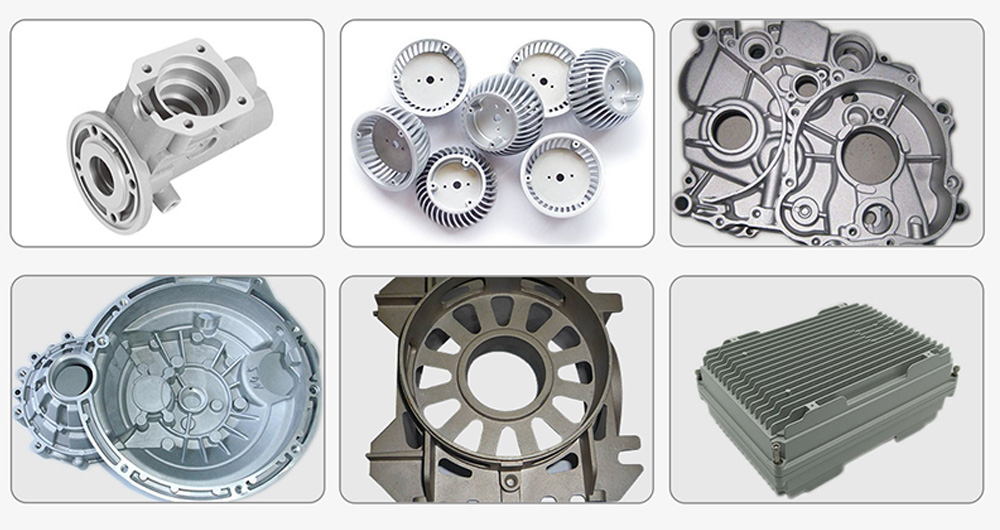

Product Material: environment-friendly aluminum alloy ADC12, ADC1, A380, A360, Alsi9cu3, Alsi12Cu1Fe, LM25, etc.,We can customize the materials specified by customers

Surface Treatment: ultrasonic cleaning, vibration, grinding, polishing, sand blasting, painting, powder spraying, electroplating, oxidation, etc.

Workshop Display:

| ||

| Die Casting Workshop | ||

|  |  |

| CNC Finishing Workshop | Testing Center | Mold Workshop |

Surface Treatment

|  |  |

| TM Wave | Grind | Polishing |

|  |  |

| Ultrasonic Cleaning | Sandblasting | Painting and powder spraying |

Conclusion:

Thank you for joining us on this journey into the world of Custom CNC Machining Services company. At YuanZhong Precision, we take pride in our ability to deliver precision and personalization with every project we undertake. Whether you’re a seasoned industry player or a startup with a groundbreaking idea, we’re here to turn your vision into reality. Reach out to us today to explore the endless possibilities of custom CNC machining!

Cecilia

Vic

Luke

Sunny

Get the latest price? We'll respond as soon as possible(within 12 hours)