How to ensure the production efficiency and quality of aluminum die casting furniture components?

2024-09-27 15:30

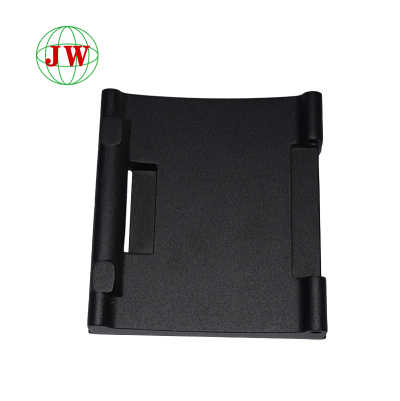

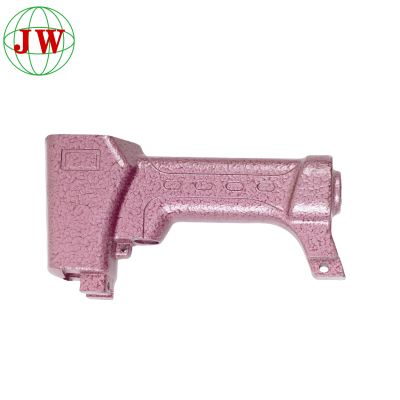

In the furniture industry, the use of aluminum die casting furniture componentshas become increasingly popular due to their numerous advantages. Aluminum die casting offers high strength, durability, and precision, making it an ideal choice for manufacturing furniture components. However, to ensure the production efficiency and quality of these components, several factors need to be considered.

I. The Importance of Aluminum Die Casting for Furniture Components

Aluminum die casting is a manufacturing process that involves forcing molten aluminum into a mold cavity under high pressure. This process allows for the production of complex shapes with high dimensional accuracy and excellent surface finish. Furniture components made through aluminum die casting offer several benefits, including:

1. Lightweight yet strong: Aluminum is a lightweight metal, which makes furniture easier to move and handle. At the same time, aluminum die casting provides high strength, ensuring that the furniture components can withstand heavy loads.

2. Durability: Aluminum is highly resistant to corrosion and wear, making it suitable for use in furniture that will be exposed to various environmental conditions.

3. Precision and consistency: Die casting allows for the production of components with tight tolerances, ensuring that each piece is identical and fits together perfectly. This precision and consistency contribute to the overall quality and appearance of the furniture.

4. Design flexibility: Aluminum die casting enables the creation of complex shapes and designs, giving furniture designers more creative freedom.

II. Factors Affecting Production Efficiency

1. Design and quality of molds: The design of the casting mold is crucial for ensuring efficient production. Molds should be designed to minimize cycle times, reduce waste, and ensure proper filling of the molten aluminum. High-quality molds made from durable materials can withstand the high pressure and temperature of the die casting process, resulting in longer service life and reduced maintenance costs.

2. Maintenance and repair: Regular maintenance and timely repair of casting molds are essential to ensure consistent production quality and efficiency. This includes cleaning the molds, inspecting for wear and damage, and making necessary repairs or replacements.

2. Equipment and Technology

1. Die casting machines: The choice of die casting machine is important for achieving high production efficiency. Modern die casting machines are equipped with advanced features such as automated controls, high-pressure injection systems, and rapid cooling capabilities. These features can significantly reduce cycle times and improve the quality of the castings.

2. Process automation: Implementing process automation can streamline production and reduce labor costs. Automated systems can handle tasks such as loading and unloading molds, injecting molten aluminum, and removing finished components, increasing production speed and consistency.

3. Material Quality

1. Aluminum alloy selection: Choosing the right aluminum alloy is crucial for ensuring the quality and performance of the furniture components. Different alloys have different properties, such as strength, ductility, and corrosion resistance. The selection should be based on the specific requirements of the furniture application.

2. Raw material purity: High-purity aluminum is essential for obtaining good casting quality. Impurities in the raw material can lead to defects such as porosity, cracks, and inclusions, which can affect the strength and durability of the components.

4. Production Planning and Scheduling

1. Demand forecasting: Accurate demand forecasting is essential for planning production volumes and schedules. This helps to ensure that there is sufficient inventory to meet customer orders without overproduction or shortages.

2. Production scheduling: Efficient production scheduling can minimize downtime and optimize the use of resources. This includes arranging production runs in a logical sequence, considering factors such as mold changes, material availability, and equipment maintenance.

III. Factors Affecting Production Quality

1. Quality Control Systems

1. Incoming material inspection: Inspecting the quality of incoming aluminum alloy and other raw materials is the first step in ensuring production quality. This includes checking for purity, chemical composition, and physical properties.

2. In-process inspection: Regular inspection during the die casting process is essential to detect and correct any defects early on. This includes checking for proper filling of the mold, absence of porosity and cracks, and correct dimensions.

3. Final inspection: A comprehensive final inspection of the finished furniture components is necessary to ensure that they meet the required quality standards. This includes visual inspection, dimensional measurement, and functional testing.

2. Employee Training and Skills

1. Technical training: Employees involved in the die casting process should receive proper technical training to understand the process, equipment, and quality requirements. This includes training on mold operation, machine settings, and quality control procedures.

2. Quality awareness: Cultivating a quality-conscious culture among employees is crucial for ensuring consistent production quality. This includes emphasizing the importance of following quality procedures, reporting defects, and taking ownership of quality.

3. Environmental Factors

1. Cleanliness and hygiene: A clean and hygienic production environment is essential for preventing contamination of the aluminum alloy and ensuring the quality of the castings. This includes regular cleaning of the production area, equipment, and molds.

2. Temperature and humidity control: Maintaining proper temperature and humidity levels in the production area can help to ensure consistent casting quality. Extreme temperatures and humidity can affect the solidification process of the molten aluminum and lead to defects.

IV. Strategies for Improving Production Efficiency and Quality

1. Continuous Improvement

1. Process optimization: Regularly review and optimize the die casting process to identify areas for improvement. This may include adjusting machine settings, improving mold design, or streamlining production workflows.

2. Technology upgrades: Stay updated with the latest advancements in die casting technology and consider upgrading equipment and processes to improve efficiency and quality.

2. Supplier Collaboration

1. Material suppliers: Work closely with aluminum alloy suppliers to ensure the supply of high-quality raw materials. This includes establishing quality agreements, conducting regular audits, and sharing technical knowledge.

2. Tooling suppliers: Collaborate with mold and tooling suppliers to ensure the design and quality of casting molds. This includes providing clear specifications, sharing design ideas, and working together to resolve any issues.

3. Quality Management Systems

1. Implement ISO 9001 or other quality management systems to ensure consistent production quality and continuous improvement. These systems provide a framework for quality planning, control, and improvement.

2. Document and track quality data to identify trends and areas for improvement. Use this data to drive decision-making and implement corrective actions.

In conclusion, ensuring the production efficiency and quality of aluminum die casting furniture components requires a comprehensive approach that considers factors such as casting tooling, equipment and technology, material quality, production planning and scheduling, quality control systems, employee training, and environmental factors. By implementing strategies for continuous improvement, collaborating with suppliers, and implementing quality management systems, furniture manufacturers can achieve high production efficiency and quality, meeting the demands of the market and providing customers with high-quality furniture products.

Get the latest price? We'll respond as soon as possible(within 12 hours)