How to effectively solve the slag inclusion in the processing of die-casting aluminum parts?

2023-04-29 15:30

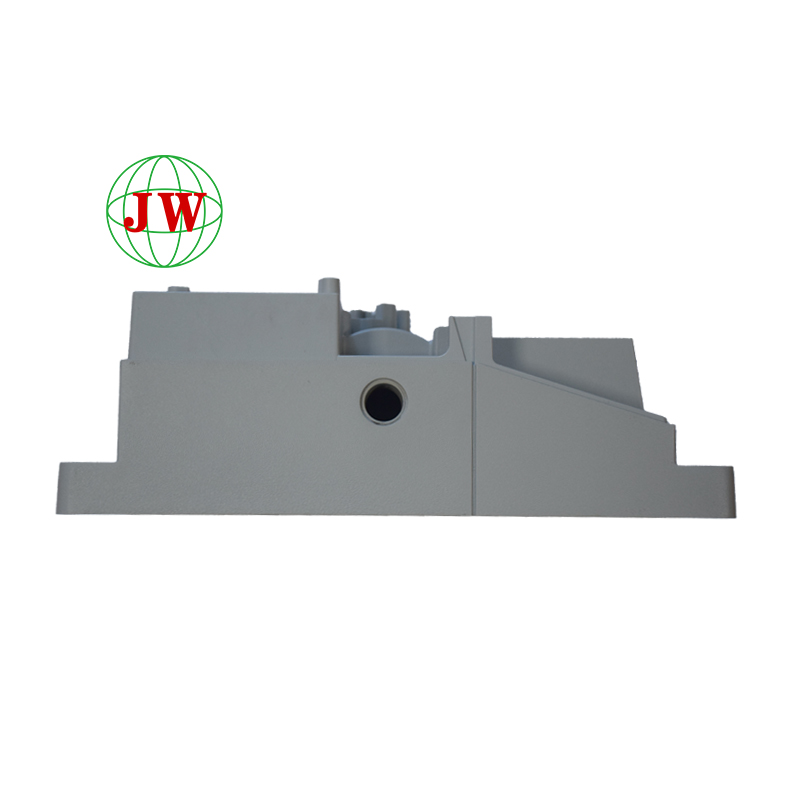

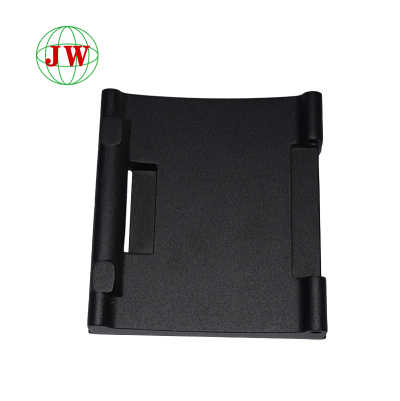

On the upper surface of die-cast aluminum parts or at the corners of the mold that are not ventilated, the fracture surface of die-cast aluminum parts is mostly gray white or yellow with slag inclusions, which can be found through X-ray fluoroscopy or mechanical processing, and can also be found during alkaline washing, acid washing, or anodizing. The main reasons for oxidation and slag inclusion in die-casting aluminum parts are as follows:

There are many reasons for the oxidation and slag inclusion of die-casting aluminum parts,

Firstly, the furnace material is not clean or the amount of recycled material used is excessive.

2. Poor design of the pouring system.

3. The slag in the pouring liquid was not completely removed.

4. Improper operation during pouring resulted in slag inclusion.

5. The casting does not have enough standing time after refining and modification treatment.

Method to prevent oxidation and slag inclusion in aluminum castings:

1. Use appropriate flux to remove slag.

2. Improve the design of the pouring system to enhance its slag blocking ability.

3. The pouring should be smooth and attention should be paid to slag blocking.

4. After refining, the alloy liquid should be left to stand for a certain period of time before pouring.

5. The furnace material should be blown through sand, and the amount of recycled material used should be appropriately reduced.

Get the latest price? We'll respond as soon as possible(within 12 hours)