Does the design of Die Casting Mold comply with the latest industry standards?

2024-10-30 15:30

Die Casting Mold design is of crucial importance in the manufacturing industry. In order to ensure the quality and efficiency of the die - casting process, it is essential to determine whether the design of die casting molds complies with the latest industry standards.

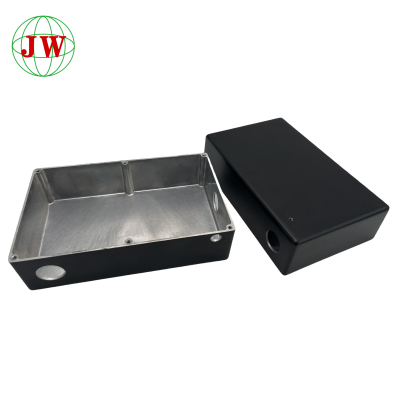

Firstly, the material selection for Die Casting Mold is a key aspect. High - quality materials that meet the standards are required to ensure the durability and heat - resistance of the mold. These materials must be able to withstand high - pressure and high - temperature environments during the die - casting operation. For example, certain alloy steels are preferred due to their excellent mechanical properties, which can prevent the mold from deforming or cracking under extreme conditions.

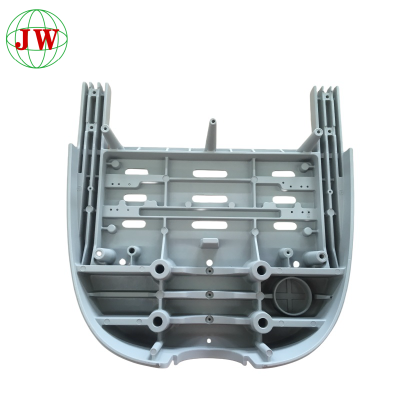

The structural design of Die Casting Mold also needs to conform to the standards. This includes considerations such as the layout of the mold cavity, the design of the runner system, and the cooling channels. The mold cavity should have precise dimensions and smooth surfaces to ensure the accuracy of the cast products. The runner system must be designed to allow for the smooth flow of molten metal, minimizing turbulence and air entrapment. Adequate cooling channels are necessary to control the temperature of the mold, enabling faster cycle times and better product quality.

In terms of safety, the design of Die Casting Mold must adhere to industry - wide safety regulations. This means incorporating features such as proper ejection mechanisms to safely remove the cast products from the mold, and safeguards to prevent operators from being injured by moving parts or hot surfaces. For instance, interlock systems can be installed to ensure that the die - casting machine only operates when the mold is properly closed and secured.

The design process of Die Casting Mold should also take into account the latest manufacturing techniques. With the advancement of technology, new design methodologies and software tools are available. These tools allow for more accurate simulation and optimization of the die - casting process. By using computer - aided design (CAD) and computer - aided engineering (CAE) software, designers can predict potential issues such as shrinkage, porosity, and warpage in the cast products, and make necessary adjustments to the mold design before actual production.

Moreover, environmental considerations are becoming an integral part of the industry standards for Die Casting Mold design. Molds should be designed to reduce material waste and energy consumption during the die - casting process. For example, optimizing the design of the runner system can minimize the amount of excess metal that needs to be trimmed and recycled.

In conclusion, to determine whether the design of Die Casting Mold complies with the latest industry standards, a comprehensive evaluation of material selection, structural design, safety features, utilization of modern manufacturing techniques, and environmental considerations is necessary. Only by meeting these standards can the die - casting molds ensure high - quality, efficient, and sustainable production

Get the latest price? We'll respond as soon as possible(within 12 hours)