Do you want to know the production process of our medical equipment casting?

2025-01-04 15:00

In the critical field of medical equipment manufacturing, the production process of casting plays a vital role in ensuring the quality, safety, and effectiveness of the final products. Do you want to know the production process of our medical equipment casting? Let's take a closer look.

It all begins with meticulous material selection. Given the sensitive nature of medical applications, we only use materials that meet the highest standards of biocompatibility and durability. For example, medical-grade stainless steels and titanium alloys are commonly employed. These materials are rigorously tested to ensure they won't cause any adverse reactions when in contact with the human body. The selection process also takes into account factors like corrosion resistance, as medical equipment may be exposed to various bodily fluids and sterilization procedures.

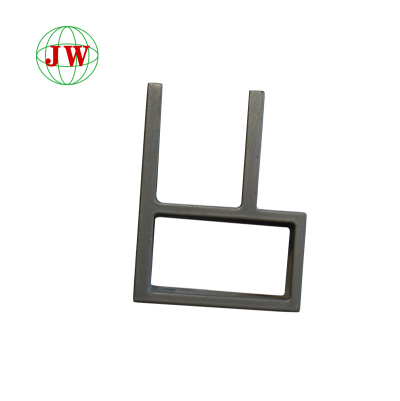

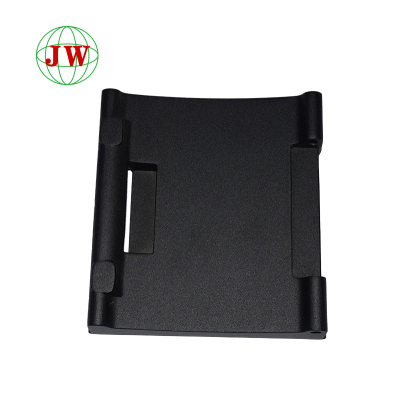

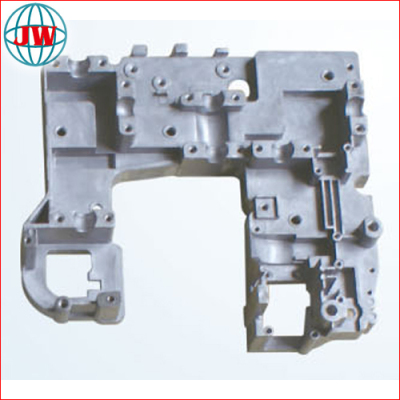

Once the materials are chosen, the mold design and fabrication stage kicks in. This is a highly precise and technical process. Our experienced engineers use advanced CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) software to create intricate mold designs. The molds need to accurately replicate the complex geometries of medical components, whether it's the delicate shape of a surgical instrument or the precise contours of a implantable device. Precision is of the utmost importance here, as even the slightest deviation could affect the functionality and fit of the final product.

After the molds are ready, the casting process itself commences. We primarily utilize techniques like vacuum casting and investment casting, which are renowned for their ability to produce high-quality, detailed parts. In vacuum casting, the molten material is poured into the mold under vacuum conditions, reducing the risk of air bubbles and ensuring a smooth surface finish. Investment casting, on the other hand, involves creating a ceramic mold around a wax pattern, which is then burned out, leaving a cavity for the molten metal. This process allows for extremely fine details and tight tolerances, essential for medical equipment.

Following casting, quality control and inspection are carried out at multiple levels. Non-destructive testing methods such as X-ray inspection and ultrasonic testing are used to detect any internal defects in the castings. Visual inspections are also performed to check for surface imperfections. Additionally, the parts are tested for mechanical properties like strength and hardness to ensure they meet the required standards for medical use.

Finally, before the medical equipment castings are ready for market, they undergo sterilization and packaging procedures. The sterilization process is carefully calibrated to eliminate any potential pathogens, using methods like autoclaving or gamma irradiation. The packaging is designed to protect the delicate components during transportation and storage, while also maintaining their sterility until they reach the end-user.

In conclusion, the production process of our medical equipment casting is a comprehensive and highly regulated journey. From material selection to final packaging, every step is meticulously executed to ensure the highest quality and safety of the medical equipment, providing healthcare professionals and patients with reliable tools for diagnosis, treatment, and care

Get the latest price? We'll respond as soon as possible(within 12 hours)