Do you understand how our component casting can improve automotive safety performance?

2025-01-17 15:30

In the fast - paced and safety - conscious world of automotive engineering, every aspect of vehicle design and manufacturing plays a crucial role in safeguarding the lives of drivers and passengers. Component casting is one such area that has a profound impact on automotive safety performance.

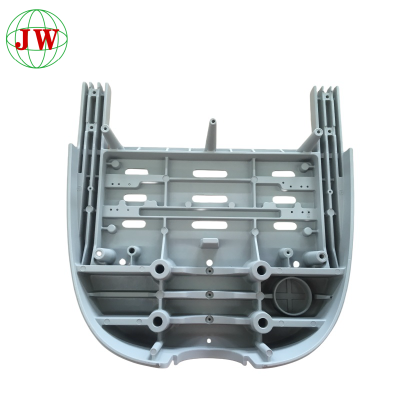

The first and foremost way component casting enhances safety is through precision. When components are cast with high precision, they fit together perfectly within the vehicle's structure. For example, in the case of engine mounts, which are responsible for securing the engine in place. If these mounts are cast accurately, they can effectively isolate engine vibrations and movements. This not only improves the driving experience but also ensures that the engine remains stable under various driving conditions. A poorly cast engine mount could lead to the engine shifting during sudden acceleration, braking, or sharp turns, potentially causing a loss of control over the vehicle.

Material Selection and Strength

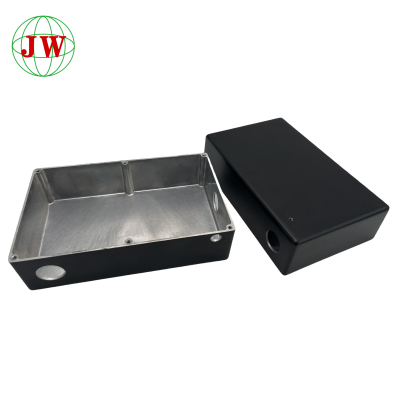

The choice of materials in component casting is of utmost importance for safety. High - strength alloys are often used in critical components such as the chassis and suspension parts. For instance, aluminum - alloy castings are widely used in modern vehicles due to their excellent strength - to - weight ratio. A strong chassis, cast from high - quality materials, can better withstand the forces exerted during a collision. It can absorb and distribute impact energy more effectively, reducing the risk of the passenger compartment being compromised. In the case of suspension components, cast from durable materials, they can maintain their structural integrity even under extreme stress, ensuring consistent handling and stability of the vehicle.

Casting for Safety - Critical Systems

Braking systems are a prime example of where component casting directly impacts safety. The brake calipers, which are often cast components, need to be precisely manufactured to ensure uniform clamping force on the brake discs. A well - cast brake caliper can provide consistent and reliable braking performance. If there are any flaws in the casting process, such as porosity or uneven thickness, it could lead to uneven braking, longer stopping distances, or even brake failure in extreme cases. Similarly, in the case of airbag housings, casting plays a vital role. These housings need to be strong enough to withstand the explosive force of the airbag deployment while also being precisely designed to direct the airbag's inflation in the right direction, protecting the occupants effectively.

Quality Control in Casting

Rigorous quality control measures during component casting are essential for ensuring safety. Advanced inspection techniques, such as X - ray and ultrasonic testing, are used to detect any internal defects in the castings. In automotive manufacturing, even a small crack or void in a casting can grow under stress and lead to catastrophic failure. By catching these defects early in the production process, manufacturers can prevent potentially dangerous situations on the road. Quality control also extends to the surface finish of the cast components. A smooth surface finish reduces the risk of stress concentrations, which could otherwise weaken the component over time.

In conclusion, component casting is an integral part of the automotive safety equation. From precision manufacturing and material selection to its application in safety - critical systems and strict quality control, it has a far - reaching impact on the safety performance of vehicles. As automotive technology continues to evolve, the importance of high - quality component casting in ensuring the safety of all road users will only increase.

Get the latest price? We'll respond as soon as possible(within 12 hours)