Do you know that our communication component die-casting has excellent durability?

2024-10-22 15:30

Communication component die - casting plays a crucial role in the modern communication industry. Our company's communication component die - casting stands out due to its remarkable durability, which is achieved through a combination of advanced techniques and high - quality materials.

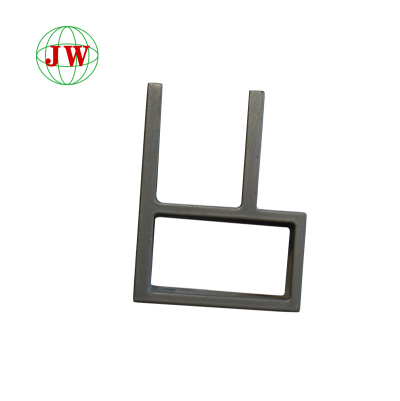

The die - casting process itself is a sophisticated manufacturing method. For communication component die - casting, we start with precise mold design. The molds are crafted with the utmost care, using state - of - the - art CAD/CAM technologies. These molds determine the shape and structure of the communication components, and their high precision is essential for ensuring durability. The smooth surface of the molds helps to produce components without any surface irregularities that could potentially lead to weaknesses.

We select materials with great care for our communication component die - casting. Commonly, we use high - grade alloys such as aluminum - based and zinc - based alloys. Aluminum alloys offer excellent strength - to - weight ratios. They are resistant to corrosion, which is vital in environments where communication equipment may be exposed to moisture or other corrosive substances. Zinc - based alloys, on the other hand, provide good mechanical properties and are known for their wear - resistance.

During the die - casting process, the molten metal is injected into the mold under high pressure. This high - pressure injection ensures that the metal fills every corner of the mold cavity uniformly. It results in a dense microstructure of the component, which contributes significantly to its durability. The components produced have a high level of integrity, with no internal voids or porosity that could lead to failure under stress.

Our communication component die - casting undergoes strict quality control procedures at every stage. From the inspection of raw materials to the final inspection of the die - cast components, we leave no stone unturned. We use advanced testing equipment to check for any potential defects. For example, we conduct hardness tests to ensure that the components have the right mechanical properties. Non - destructive testing methods like ultrasonic inspection are also employed to detect any internal flaws that may not be visible to the naked eye.

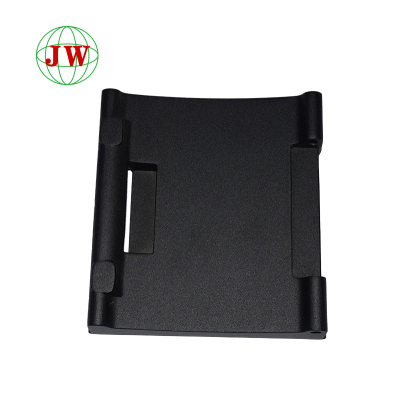

The durability of our communication component die - casting is also enhanced by post - processing techniques. After die - casting, some components may undergo surface treatments such as plating or coating. Plating with materials like nickel or chrome can provide an additional layer of protection against corrosion and wear. Coating with certain polymers can improve the component's resistance to environmental factors such as UV radiation and chemical exposure.

In real - world applications, the durability of our communication component die - casting is put to the test. Communication components are often required to operate under various conditions, including temperature fluctuations, mechanical vibrations, and electrical stress. Our die - cast components have demonstrated outstanding performance in these demanding environments. For example, in base station equipment, our components can withstand continuous operation for long periods without any degradation in performance. They maintain stable electrical connections and mechanical stability, ensuring the smooth operation of the communication systems.

Moreover, our research and development team is constantly working on improving the durability of our communication component die - casting. We study new materials and manufacturing techniques to stay ahead in the market. We collaborate with universities and research institutions to explore innovative solutions. By constantly evolving and improving our die - casting process, we aim to provide communication components with even higher levels of durability in the future.

In conclusion, the excellent durability of our communication component die - casting is the result of our attention to detail in every aspect of the manufacturing process, from mold design and material selection to quality control and post - processing. It is this durability that makes our communication components a reliable choice for the ever - evolving communication industry.

Get the latest price? We'll respond as soon as possible(within 12 hours)