Can our furniture component die-casting technology meet your design requirements?

2024-10-23 15:00

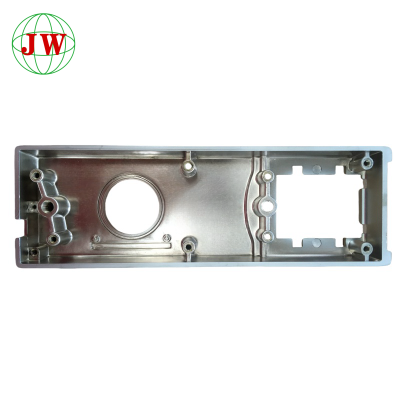

In the world of furniture manufacturing, die - casting technology has emerged as a revolutionary method for creating high - quality components. Our furniture component die - casting technology is designed with the aim of meeting a wide range of design requirements.

Our die - casting process begins with a team of highly skilled engineers and designers. They work closely with clients to understand their specific design requirements. Whether it's a sleek, modern look or a more traditional and ornate style, we have the expertise to translate these visions into reality.

The furniture component die - casting technology we employ offers several advantages. Firstly, it allows for great precision. We can produce components with intricate details, sharp edges, and smooth surfaces, which are often crucial for furniture design. For example, decorative elements like intricate patterns on table legs or chair backs can be accurately replicated through die - casting.

Secondly, we have a wide selection of materials available for die - casting. Different metals and alloys can be chosen based on the desired properties of the furniture component. If strength and durability are required, we can use alloys that offer high - tensile strength. On the other hand, if a lighter weight component is needed, we can select materials with lower density while still maintaining the necessary structural integrity.

Our manufacturing facilities are equipped with state - of - the - art die - casting machines. These machines are capable of applying the precise amount of pressure needed to ensure that the molten metal fills the mold cavity completely and uniformly. This results in components with consistent quality and no internal defects such as porosity.

In terms of customization, our furniture component die - casting technology truly shines. We can create unique molds for each client's design. This means that if you have a one - of - a - kind design idea for your furniture, we can make it happen. Whether it's an unusual shape, a specific size, or a combination of functional and aesthetic features, we have the capability to produce the corresponding die - cast components.

Moreover, our quality control procedures are rigorous. Each die - cast furniture component undergoes multiple inspections at different stages of production. We check for dimensional accuracy, surface finish, and mechanical properties. Any component that does not meet our high standards is rejected or re - worked to ensure that only the best - quality products reach our clients.

We also offer post - die - casting services. This includes surface treatments such as polishing, plating, and painting. These treatments not only enhance the appearance of the furniture components but also provide additional protection against corrosion and wear, further extending their lifespan.

In conclusion, our furniture component die - casting technology is highly capable of meeting diverse design requirements. From the initial design consultation to the final production and quality assurance, we strive to deliver furniture components that combine both functionality and aesthetic appeal, satisfying the most demanding of clients.

Get the latest price? We'll respond as soon as possible(within 12 hours)