Do you have any technical questions about die - casting of communication components?

2024-11-04 03:30

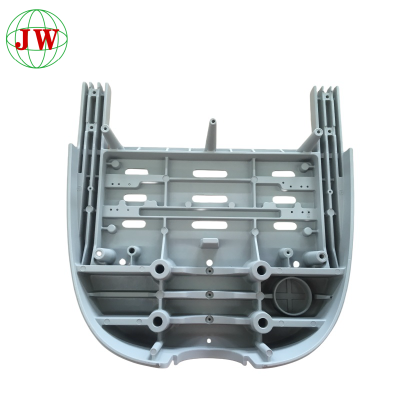

In today's highly connected world, communication components play a crucial role in ensuring seamless transmission of signals and data. Die - casting of communication components has emerged as a popular manufacturing method due to its ability to produce complex shapes with high precision and efficiency. However, like any manufacturing process, it comes with its own set of technical challenges and questions.

One of the primary technical questions related to die - casting of communication components is material selection. The choice of material is critical as it directly impacts the performance and durability of the final product. For communication components, materials need to have excellent electrical conductivity, thermal conductivity, and mechanical strength. Some commonly used materials for die - casting of communication components include aluminum alloys, zinc alloys, and magnesium alloys. Each material has its own unique properties and advantages, and the selection depends on factors such as the specific application requirements, cost considerations, and manufacturing process limitations.

Another important technical question is mold design. The mold is the heart of the die - casting process, and its design plays a crucial role in determining the quality and productivity of the cast components. For die - casting of communication components, the mold design needs to take into account factors such as the complexity of the component shape, the required dimensional accuracy, and the cooling requirements. Advanced computer - aided design (CAD) and computer - aided engineering (CAE) tools are often used to optimize the mold design and ensure that it can meet the stringent requirements of communication component manufacturing.

The die - casting process parameters also pose technical questions. Parameters such as injection pressure, injection speed, melt temperature, and cooling time need to be carefully controlled to ensure the quality and performance of the cast components. For die - casting of communication components, these parameters need to be optimized to achieve the desired electrical and mechanical properties. Process monitoring and control systems are often employed to ensure that the process parameters are maintained within the specified ranges and to detect any deviations or abnormalities in real time.

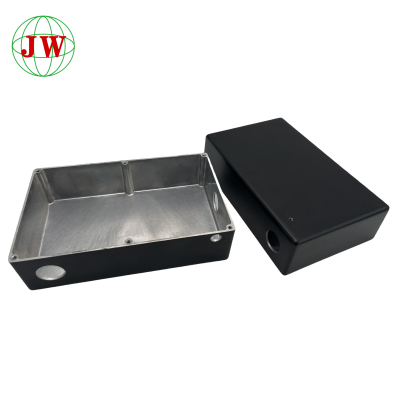

Surface finish is another area of concern for die - casting of communication components. Communication components often require a smooth and defect - free surface to ensure proper electrical insulation and signal transmission. Various surface treatment methods such as polishing, plating, and anodizing can be used to improve the surface finish of the cast components. However, these methods need to be carefully selected and applied to ensure that they do not adversely affect the electrical and mechanical properties of the components.

Quality control is a critical aspect of die - casting of communication components. Due to the high precision and reliability requirements of communication systems, strict quality control measures need to be implemented to ensure that the cast components meet the required standards. This includes inspections for dimensional accuracy, surface finish, mechanical properties, and electrical conductivity. Non - destructive testing methods such as X - ray inspection, ultrasonic testing, and magnetic particle inspection can be used to detect internal defects and ensure the integrity of the cast components.

In conclusion, die - casting of communication components is a complex and challenging manufacturing process that requires careful consideration of various technical factors. By addressing these technical questions and implementing appropriate solutions, manufacturers can ensure the production of high - quality communication components that meet the demanding requirements of today's digital age

Get the latest price? We'll respond as soon as possible(within 12 hours)