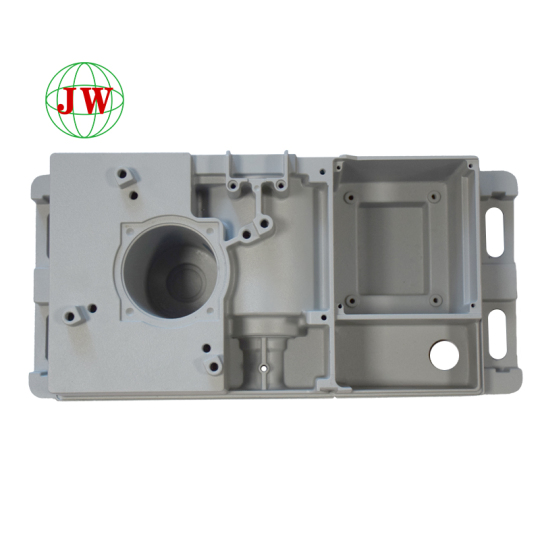

Hot Products

About Us

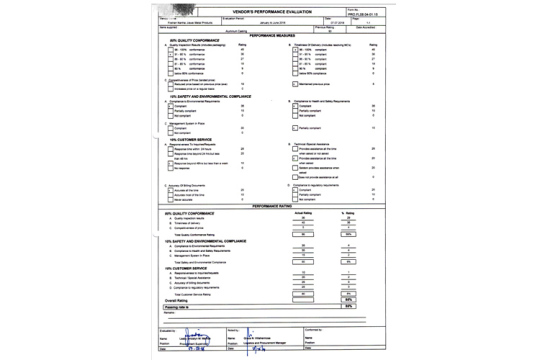

Foshan Nanhai Jiawei Metal Products Co., Ltd. has a history of more than 30 years since its establishment in 1992, with strong economic strength. With the rapid development of business, the production scale has also been expanding. In the second half of 2001, the new plant began to be built, and was completed and put into operation in 2003. Now the company covers an area of 21800 square meters, including 9500 square meters of factory buildings, 780 square meters of office buildings and 2780 square meters of dormitories. There are 165 employees, including 46 engineers and technicians.

More

News

-

05/05-2024

Innovative Non-Toxic Cookware Revolutionizes Culinary ExperienceIn the dynamic culinary industry, manufacturers are responding to the demand for safe and efficient cookware. Aluminum die-cast and non-stick cookware, alongside BBQ accessories and Teflon pans, are at the forefront. The quest for the best nontoxic nonstick pan has led to revolutionary advancements. Our company leads this charge with premium nontoxic nonstick cookware, boasting durability, safety, and performance. From aluminum die-cast durability to superior non-stick coatings, our products redefine culinary excellence.

-

04/24-2025

Do you need any suggestions on the material selection of communication components?Material selection for communication components is vital. Aluminum alloys are popular for their lightweight, corrosion - resistance, and thermal conductivity, suitable for various devices. Zinc alloys offer precision and cost - efficiency, ideal for small parts like connectors. Magnesium alloys are ultra - light and good for damping, used in aerospace. Copper alloys ensure excellent electrical and thermal performance for parts needing conductivity. Polymer composites serve specialized needs, providing insulation and cost - effective solutions for non - metallic components. Each material has unique advantages for different communication applications

-

04/23-2025

What is the service life of die castings?The service life of die castings is determined by multiple factors. Material selection, such as aluminum or zinc alloys, impacts durability, with some offering better corrosion resistance or wear - resistance. The die - casting process itself, including die design, injection parameters, and quality control, is crucial; improper settings or undetected defects can shorten lifespan. Environmental exposure and application - specific stresses also play significant roles, with corrosive environments and high mechanical loads accelerating degradation. Maintenance and post - processing, like heat treatment and surface coating, can further extend the life of die castings